Kansas Geological Survey, Public Information Circular (PIC) 31

A complete version of this PIC is available as a pdf document.

Catherine S. Evans

Kansas Geological Survey

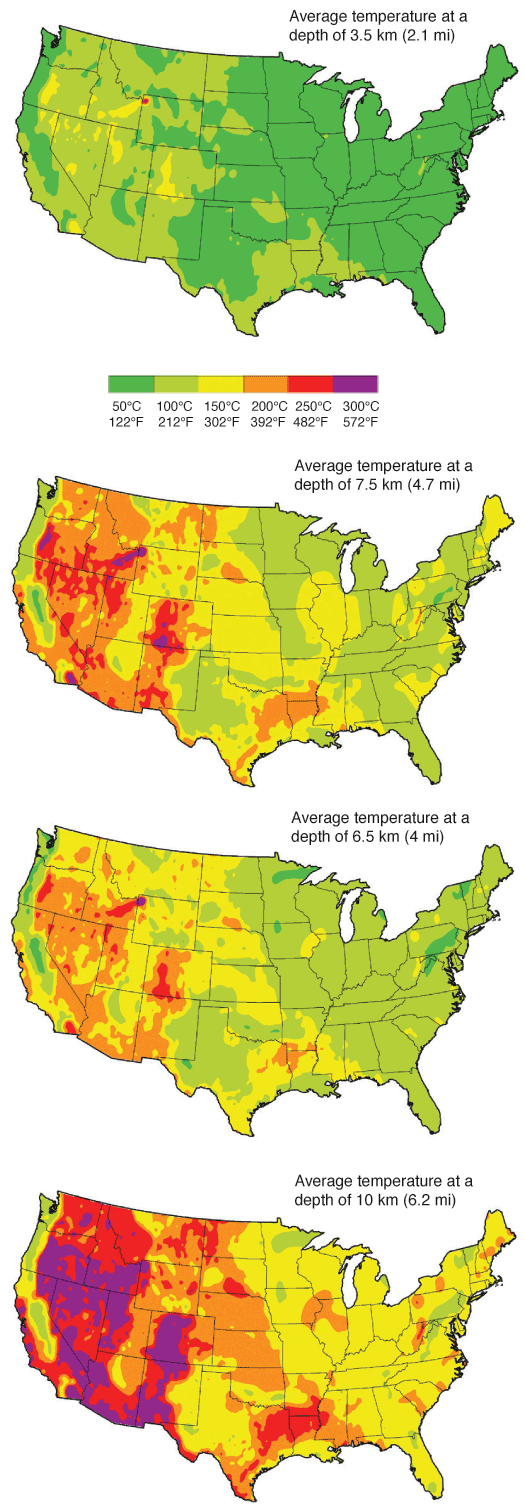

Geothermal energy--heat generated and stored in the earth's interior--on average diminishes in intensity from core to mantle to crust. Although deeper is generally hotter, the earth's heat is not evenly distributed (fig. 1). Within the crust, rocks 100°C (212°F) or higher are sometimes found less than a mile from the surface, as is the case in areas of the United States west of the Rocky Mountains. In Kansas, equivalent temperatures are generally 6 mi (10 km) or more deep.

Figure 1--Subsurface temperatures at four depths in the conterminous United States. Adapted from The future of geothermal energy (Tester et al., 2006).

Geothermal energy can be tapped and transported from subsurface rocks via ground water or other fluids and, depending on temperature, used through three methods to produce electricity, sustain industries, or heat homes. Large-scale geothermal power plants generate electricity with heat carried up in ground water through deep wells drilled into the hottest accessible rock layers. Direct-use systems run on more moderate-temperature resources piped straight into resorts and spas or are used to dehydrate food, pasteurize milk, melt snow from sidewalks, and grow fish or greenhouse plants. Geothermal heat pump (GHP) systems rely on tepid ground temperatures found within 10 ft (3 m) of the surface to heat and cool interior spaces.

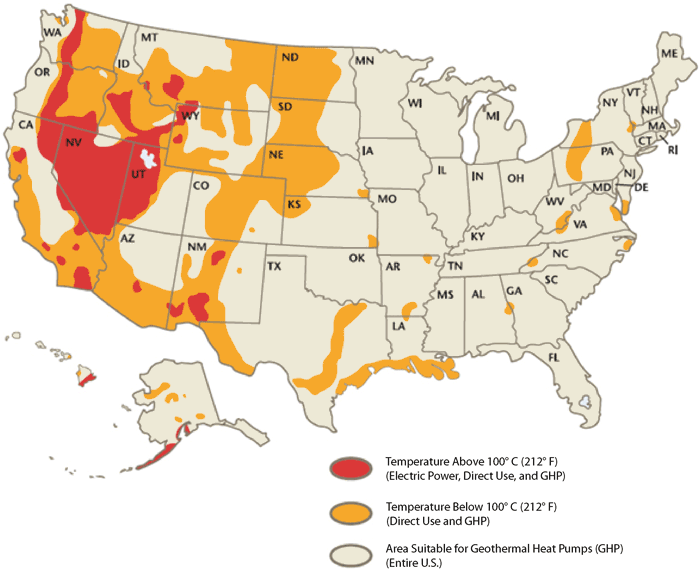

All large-scale geothermal electrical power plants in the United States are west of the Rockies where 100°C (212°F) or hotter ground water has been found in large underground reservoirs within about 2.5 mi (4 km) of the surface, a depth economically accessible with current drilling technology (Duffield and Sass, 2004). East of the Rockies water-bearing rocks hot enough to generate electricity are too deep to be easily accessed. Direct-use systems are in operation in several locations, east and west of the Rockies, but Kansas has no direct-use systems and limited near-surface geothermal resources to run them (fig. 2).

Figure 2--Accessible geothermal resources suitable for electric power production, direct-use systems, and GHP systems in the United States. Adapted from Geothermal: The energy under our feet (NREL, 2006).

Geothermal heat pump systems in Kansas, however, are on the increase. Capable of functioning year round on nearly constant 50°F to 60°F (10°C to 15°C) geothermal resources and on significantly less electricity than traditional systems, GHPs are being used to heat and cool everything from small homes to large multi-building complexes. In fact, because almost every inhabited place on earth has this resource within 10 ft (3 m) of the surface regardless of climate, GHP use is on the rise worldwide.

This Circular provides information on the four basic GHP systems, examples of systems in Kansas, and information about governmental regulations on installation and use, tax incentives to help offset installation costs, and voluntary performance rating systems that compare GHP systems for consumers. It also includes background on geothermal power production in the United States, the benefits of using geothermal energy, and challenges facing the geothermal energy industry. In Kansas geothermal resources hot enough to maintain large-scale power plants and even direct-use systems are deep and, thus, currently too expensive to access. However, advancements in drilling technology might make those forms of production possible for Kansas in the future.

Temperatures at a uniform depth in the earth's crust vary with rock type. How much heat a rock retains is determined by its density and composition. The greatest influence on temperature variations in the crust, however, is molten rock, or magma, that pushes up from the mantle and transfers heat to the cooler rocks in its path (DOE, 2008). While molten rock rises mainly along such tectonic boundaries as the "Ring of Fire" rimming the Pacific Plate, anomalous plumes in plate interiors create isolated hotspots such as those in Yellowstone National Park (fig. 3). Steam venting from Old Faithful geyser has been recorded above 350°F (176°C; NPS, 2011).

Figure 3--Half of the earth's geothermal features, including more than 300 geysers, are found in Yellowstone National Park (NPS, 2011).

In hotspots around the world geothermal power plants have been built to generate electricity with steam and hot water pumped up through wells drilled into extensive underground geothermal reservoirs. Large-scale production of geothermal resources started in the United States when the first power plant opened in 1960 at The Geysers geothermal area of California. The Geysers area now has the largest group of geothermal power plants in the world and, along with the Imperial Valley in south-central California, produces most of the country's geothermal energy (Duffield and Sass, 2004).

Generating large quantities of electricity requires an extensive geothermal field. As with oil and gas fields, the size and depth of each field can only be determined through drilling multiple wells. For geothermal exploration to be successful, it is essential to locate not only relatively shallow and extensive heat but also ground water. Hot rocks are useless for geothermal production without water to transport the heat up to the surface. Large-scale geothermal power plants, along with direct-use systems and some heat pumps, rely on ground water pumped from wells drilled into porous and permeable rocks.

If new methods currently being tested to recover heat from low-permeable or dry rocks are successful, that dependence on ground water to move heat to the surface could diminish. A proven but still evolving technology called enhanced geothermal systems (EGS) targets hot but low-permeable or dry rocks, even magma, whose massive heat resources are irrecoverable using traditional technology (DOE, 2010a). With EGS, subsurface rocks are fractured to allow greater circulation of ground water or injection of water from the surface into dry but hot rock. Current drilling techniques and equipment, originally designed for oil and gas recovery, are being adapted to recover more of the bountiful energy deep in the earth (Pew Center, 2009).

Geothermal energy has the advantage of being far more abundant and cleaner than some energy resources and more readily available than others. Just 1% of the geothermal energy contained in the top 6 mi (~10 km) of the earth's crust greatly exceeds the amount of oil and gas in all of the world's reserves (Duffield and Sass, 2004). Cleaner than processes fueled by oil, gas, or coal, geothermal systems don't require transportation, storage, or combustion of fuel. They also take up relatively little space, which can be shared with livestock grazing and other uses (DOE, 2008). Compared to renewable energy production methods dependent on wind, solar, and other alternative energies, geothermal operations are not limited by climate and weather and can run year-round, 24 hours a day.

Environmental concerns that must be considered during geothermal exploration include alteration of hot springs and geothermal reservoirs, contamination of ground water, and creation of underground voids that could cause land subsidence or seismic activities (DOE, 2010a). Also, while heat in the earth's interior is constantly regenerating, localized geothermal reservoirs have shown signs of decline. Various strategies, such as water recycling, are already being implemented to prolong the life of The Geysers in California and other highly used geothermal resources. Advancement of Enhanced Geothermal Systems (EGS) might provide a long-term solution.

Starting in 2009 the U.S. Department of Energy (DOE) awarded funding to a variety of geothermal energy projects. Part went to a coalition of agencies organized by the Association of American State Geologists, including the Kansas Geological Survey, to locate existing subsurface data stored in hundreds of individual databases and file cabinets throughout the country. The project will make information on the composition, temperature, water content, and permeability of underground rocks much more accessible, eliminating duplication of effort by researchers, businesses, and individuals exploring geothermal opportunities.

Insulated by surface rocks and soils, subsurface rocks and soils just 10 ft (3 m) down are a near-constant 50°F to 60°F (10°C to 15°C) year-round within the most populated latitudes on the planet (USGS). As a result, geothermal heat pumps (GHPs)--sometimes called ground source heat pumps or geoexchange systems--can function almost everywhere people live.

GHPs heat and cool interior spaces using water or other fluids to bring warmer-than-outdoor-air heat out of the ground in the winter and carry hot interior air down into the cooler-than-outdoor-air ground in the summer. With added equipment, they can also heat floors and domestic water and separately heat or cool zones within a building. An entire system normally includes underground pipes (or loops), ductwork to disperse air throughout the building, an indoor conditioning coil, at least one compressor, and one or more refrigerant-to-earth heat exchangers (DOE, 2008; AHRI, 2010).

Heat is transferred up or down through water or other fluids running in pipes in the ground, or, occasionally, laid on the bottom of a pond. Three of the four basic GHP systems (fig. 4) have closed loops. That is, fluid used to transfer heat in these systems runs in and out of the building in self-contained pipes. The fourth, the open-loop system, operates on ground water pumped up through wells or, less of-ten, on surface water in ponds or lakes.

Figure 4--The four basic types of geothermal heat pump systems. Adapted from Geothermal basics (DOE, 2008).

|

Horizontal closed-loop system: Pipes buried in trenches at least 4 ft (1.2 m) deep are laid side by side, in two rows stacked vertically, or looped in a space-saving SlinkyTM mode (shown here). This system requires more land than other methods but is cost effective for residential use when sufficient land is available. |

|

Pond/lake closed-loop system: Underground supply line pipe runs from building to pond or lake then coiled at least 8 ft (2.4 m) under surface to prevent freezing. This may be the lowest cost option but requires a water body that meets minimum volume, depth, and quality criteria. |

|

Vertical closed-loop system: Pipes connected at the bottom with U-bend are placed in holes about 4 inches (10 cm) in diameter drilled 20 ft (6 m) apart and generally 100 to 400 ft (30.5-122 m) deep. Horizontal pipes laid in trenches connect loops to building. This method is used when land is limited, often the case with commercial property, or when soil is too shallow for trenching. |

|

Open-loop system: Water pumped into the building from a well (shown here), pond, or lake is used as the heat-exchange fluid. Water circulated through the system is returned to the ground through a well or discharged on surface according to local regulations. This option requires an adequate supply of relatively clean water. |

Unlike conventional heating and cooling systems and air-source heat pumps, GHPs rely on consistently moderate year-round ground temperatures rather than air temperatures that rise and fall hour to hour, season to season. GHPs often use 25% to 50% less electricity than conventional HVAC (Heating, Ventilating, and Air Conditioning) systems, can be installed in a new building or retrofitted to an old one, and--with few moving parts--are relatively easy to maintain (DOE, 2008). Although GHP systems use a small amount of electrical energy to force heat to flow and bring tepid air to room temperature, they use no other fossil-fuel source.

The greatest drawback of a GHP system is the initial installation cost, which can be several times higher than that of a conventional system and involves drilling or trenching for placement of underground pipes. Over several years, however, those costs may be offset by low operating costs because the system functions on constant 50°F to 60°F ground temperatures rather than air temperatures that may vary from -10°F to 110°F. Maintenance costs also tend to be low in GHP systems, and tax incentives can help alleviate upfront costs.

The first geothermal heat pump systems in the United States were installed in 1948 (DOE, 2008). In 1975 fewer than 20 completion permits for geothermal wells and boreholes were submitted in Kansas but by 2010 nearly 250 were (fig. 5). Although the number of permits submitted has fluctuated from year to year, it has generally risen since the early 1990s. Permits are not required for horizontal closed-loop GHP systems whose pipes are laid in trenches or ponds rather than boreholes, so the total number of GHP systems installed annually in Kansas is not available. However, the rise in drilling permits for vertical open- and closed-loop systems reflects an upward trend in geothermal energy use in the state.

Figure 5--Number of permits filed for geothermal wells and boreholes in Kansas from 1975 to 2010.

Geothermal heat pump systems in Kansas, large and small, are retrofitted to existing structures or installed during construction. In Lawrence in the late 2000's, renovation of the historic limestone Castle Tea Room, built as a residence in 1894 and now used for special events, included installation of a geothermal heat pump system that provides room heating and cooling and hot-water radiant floor heat-ing.

The expansive, recently constructed Regional Correctional Facility at Fort Leavenworth spans seven buildings and includes a GHP system with 480 bore holes drilled up to 280 ft (85 m) deep. Ninety-five heat pumps at the facility provide heating, cooling, and refrigeration (JE Dunn, 2011; U.S. Engineering, 2009). The U.S. military also has installed geothermal systems at Fort Riley in Geary County and Forbes Field in Topeka.

After a devastating April 2007 tornado leveled much of Greensburg, Kansas, the town has been rebuilding with an emphasis on green technology, including geothermal energy. Several new or rebuilt homes and buildings, including city hall, an arts center, the K-12 school campus, and a business incubator (fig. 6), feature geothermal heat pump systems. The 1914 Kiowa County Courthouse, damaged but among the few buildings left standing, was renovated to include a GHP system with thirty-two 300-ft (92-m)-deep wells that eliminates the need for centralized boilers and chillers (NREL, 2009; Greensburg Greentown, 2011).

Figure 6--Interior equipment for the 21-well geothermal heat pump system in the 9,580 ft2 (891 m2) SunChips® Business Incubator, Greensburg, Kansas. From Low-temperature geothermal resources (DOE, 2010b).

Federal government standards and codes for GHP systems are no different than for any HVAC system. Kansas wells for open-loop systems and boreholes for closed-loop systems must be drilled according to Kansas Department of Health and Environment (KDHE) regulations by a KDHE-licensed water-well contractor, who must submit a WWC-5 water well form to KDHE upon completion (KDHE, 2009a; KDHE, 2009b). Information on the form can be found at http://www.kdheks.gov/waterwell/.

The Kansas Geological Survey maintains a Water Well Completion Records (WWC-5) database that contains the WWC-5 forms filed for all water wells and boreholes drilled for geothermal heat pump systems submitted in the state. The database is accessible on the Survey website at http://www.kgs.ku.edu/Magellan/WaterWell/.

For those parts of Kansas where well contractors need to avoid areas with shallow oil, gas, and salt-water zones, KDHE provides information on how to identify those zones in a Technical Assistance Bulletin (http://www.kdheks.gov/waterwell/download/GeothermalWellsTechAssistDoc.pdf).

Two non-binding performance rating systems with standards above those dictated by law have been developed--one by the Air-Conditioning, Heating, and Refrigeration Institute (AHRI) and the other through the Federal government's ENERGY STAR program. The AHRI and ENERGY STAR energy-efficient rating standards are designed to help consumers evaluate geothermal heat pumps, which tend to far exceed minimum government standards, and a variety of other products. Companies are not required to adhere to the standards, but products that meet them earn AHRI certification and/or the ENERGY STAR label.

AHRI is a voluntary, nonprofit organization composed of the manufacturers of air conditioning, refrigeration, and heating products who produce most of the air conditioning and refrigeration machinery manufactured in the United States. The AHRI's Directory of Certified Direct Geoexchange Heat Pumps, which provides ratings for residential and commercial models of participating manufacturers, can be accessed at http://www.ahridirectory.org/ahridirectory/pages/home.aspx (AHRI, 2010).

ENERGY STAR is a joint program of DOE and the U.S. Environmental Protection Agency (EPA). The program's guidelines are set by the EPA and can be viewed along with tips on hiring a GHP contractor and information on current tax credits at http://www.energystar.gov (ENERGY STAR, 2011).

Homeowners who install geothermal heat pumps from October 3, 2008, to December 31, 2016, are eligible for a Federal tax credit equal to 30% of the unit's cost. A maximum of $2,000 can be claimed for qualified geothermal heat pumps installed before January 1, 2009. Systems installed after that time are not subject to the maximum limit under a provision of the American Recovery and Reinvestment Act (ARRA) of 2009. More information on Federal income tax incentives for geothermal energy and other energy-efficient products and technology is available from the Tax Incentive Assistance Project (TIAP), which is sponsored by a coalition of public interest nonprofit groups, government agencies, and other organizations, at http://energytaxincentives.org (TIAP, 2009).

The Kansas Energy Office, a division of the Kansas Corporation Commission (KCC), also provides access to the Federal tax credit information for geothermal heat pumps along with links to information on incentives for other alternative energies, including solar and wind energy, electric vehicles, and fuel-cell tax credits at http://www.kcc.state.ks.us/energy/other_programs.htm (Kansas Energy Office, 2011).

Thanks to Deb Stewart and Richard Harper for information on geothermal wells in Kansas; to Rex Buchanan, Shane Lyle, Dave Newell, and Bob Sawin for reviews and comments; to Dana Adkins-Heljeson for the chart in fig. 5, and to Marla Adkins-Heljeson for editing and layout.

AHRI, 2010, Certified Product Directory--Direct Geo Exchange: 870: Air-Conditioning, Heating, and Refrigeration Institute (AHRI), http://www.ahridirectory.org/ahridirectory/pages/home.aspx (accessed March 2011).

DOE, 2008, Geothermal Basics: U.S. Department of Energy, http://www1.eere.energy.gov/geothermal/geothermal_basics.html (accessed March 2011).

DOE, 2010a, Federal Interagency Geothermal Activities: Geothermal Technology Program, Office of Energy Efficiency and Renewable Energy, U.S. Department of Energy (DOE), http://www1.eere.energy.gov/geothermal/pdfs/ngap.pdf (accessed March 2011).

DOE, 2010b, Low-temperature geothermal resources: U.S. Department of Energy Geothermal Technologies Program Fact Sheet, http://www1.eere.energy.gov/geothermal/pdfs/low_temp_overview.pdf (accessed March 2011).

Duffield, W. A., and Sass, J. H., 2004, Geothermal energy--Clean power from the earth's heat: U.S. Geological Survey, Circular 1249, http://pubs.usgs.gov/circ/2004/c1249/ (accessed March 2011).

ENERGY STAR, 2011, http://www.energystar.gov/ (accessed March 2011).

Greensburg Greentown, 2011, http://www.greensburggreentown.org/ (accessed March 2011).

JE Dunn, 2011, Midwest joint regional correctional facility--Ft. Leavenworth, KS: JE Dunn Construction Group, Inc., http://www.jedunn.com/portfolio/0/1807891 (accessed March 2011).

Kansas Energy Office, 2011, http://www.kcc.state.ks.us/energy/other_programs.htm (accessed March 2011).

KDHE, 2009a, Class V underground injection control (UIC) heat pump and air conditioning return flow well requirements: Kansas Department of Health and Environment, http://www.kdheks.gov/uic/download/UICV-3.pdf (accessed March 2011).

KDHE, 2009b, Procedure for geothermal closed loop heat pump systems using vertical boreholes: Kansas Department of Health and Environment, http://www.kdheks.gov/waterwell/download/WWP-8_2009.pdf (accessed March 2011).

NPS, 2011, Yellowstone brochure: National Park Service, http://www.nps.gov/yell/index.htm (accessed March 2011).

NREL, 2006, Geothermal--The energy under our feet: National Renewable Energy Laboratory, http://www.nrel.gov/docs/fy07osti/40948.pdf (accessed March 2011).

NREL, 2009, Rebuilding Greensburg, Kansas, as a Model Green Community--A case study: National Renewable Energy Laboratory, http://www.nrel.gov/docs/fy10osti/45135-1.pdf (accessed March 2011).

Pew Center, 2009, Geothermal energy: Pew Center on Global Climate Change, http://www.pewclimate.org/technology/factsheet/geothermal (accessed March 2011).

Tester, J. W., Anderson, B. J., Batchelor, A. S., Blackwell, D. D., DiPippo, R., Drake, E. M., Garnish, J., et al., 2006, The future of geothermal energy--Impact of enhanced geothermal systems (EGS) on the United States in the 21st Century: Massachusetts Institute of Technology, http://www1.eere.energy.gov/geothermal/future_geothermal.html (accessed March 2011).

TIAP, 2009, On-site renewables tax incentives: Tax Incentive Assistance Project (TIAP), http://energytaxincentives.org/business/renewables.php (accessed March 2011).

U.S. Engineering, 2009, Fort Leavenworth Regional Correctional Facility: U.S. Engineering Company, http://www.usengineering.com/our-work/markets/government/fort-leavenworth-regional-correctional-facility (accessed March 2011).

Kansas Geological Survey, Public Outreach

Comments to webadmin@kgs.ku.edu

Web version April 21, 2011

http://www.kgs.ku.edu/Publications/PIC/pic31.html