Kansas Geological Survey, Public Information Circular (PIC) 19

A complete version of this PIC is available as a pdf document.

![]()

![]()

![]()

Kansas Geological Survey, Public Information Circular (PIC) 19

A complete version of this PIC is available as a pdf document.

K. David Newell, Robert S. Sawin, and Lawrence L. Brady

Methane, the main component of natural gas, has been a product of the petroleum industry for years. Many of us use natural gas in our homes--in our furnaces, water heaters, and stoves. Now, an unconventional source of natural gas--methane from coalbeds--has generated interest in eastern Kansas.

Coalbed methane (CBM) is natural gas that occurs in coalbeds. The geological process that turns plant material into coal generates methane gas.

Coalbed methane now accounts for about 9 percent of the total annual gas production in the United States. Large quantities of methane are being developed from coalbeds in several intermontane basins in Montana, Wyoming, New Mexico, and Colorado, in parts of the Black Warrior basin in Alabama, and in basins in the central Appalachians.

In Kansas, most of the activity has been in the southeastern part of the state, primarily Montgomery, Neosho, Wilson, western Labette, and eastern Chautauqua counties; however, other parts of eastern Kansas that are underlain by coalbeds also have potential for coalbed methane production (fig. 1). These areas are the Forest City and Cherokee basins east of the Nemaha uplift, a subsurface geologic structure that runs from Oklahoma City, Oklahoma, north through El Dorado, Kansas, and just east of Manhattan, Kansas.

Figure 1--Locations of sections (nominally 1 square mile) in eastern Kansas in 2012 with recorded coalbed methane production (red) and sections with at least one well drilled for coalbed methane, but with no production recorded (gray). Major gas pipelines are in orange.

Coal is the most abundant energy source in the world. Coal deposits have been mined in Kansas for nearly 160 years, mostly in southeastern Kansas, where surface and subsurface mines have produced over 300 million tons of coal. Bituminous (soft grade) coal resources of Pennsylvanian age, deposited about 300 million years ago, are widespread in eastern Kansas and constitute nearly all the coal resources in the state. Coal production in Kansas peaked during World Wars I and II. Today, only small surface mines occasionally operate in eastern Kansas, mostly in Miami, Linn, Crawford, and Bourbon counties. Kansas coal is used mainly as a blending fuel with western coal from Wyoming for local power generation in eastern Kansas and western Missouri.

Coal forms from plant material that was accumulated in ancient swamps and bogs at rates fast enough to prevent decay. Upon burial, the material is first converted to peat. Through time, as temperature and pressure increase with further burial, peat is converted to coal (it takes about 10 feet of peat to make 1 foot of coal). During this process, large quantities of methane-rich gas are generated and stored within the coal. The gas is not stored in its compressed gaseous state as it commonly is in the pores of sandstones and limestones, but rather it is chemically attached, or adsorbed, to the carbon atoms of the coal. Coal can store surprisingly large volumes of gas, up to six or seven times as much gas as a conventional gas reservoir (typically sandstone or limestone) of equal rock volume. The amount of gas in coal depends on the degree of alteration the coal has undergone in the burial process, the depth below the surface, and the pressure of the reservoir.

Coalbed gas is mainly composed of methane (CH4), the principal constituent of natural gas. Coalbed methane is what geologists call a sweet gas because it typically contains very few impurities such as hydrogen sulfide, nitrogen, or carbon dioxide, all normally found in natural gas. Coalbed methane, when burned, generates as much heat as petroleum-based natural gas.

Coal contains gas and large amounts of water. Once the confining pressure on the coal is relieved (for example, by drilling and pumping), the gas is slowly released from the coal. Naturally occurring fractures, called cleats, provide the plumbing system within the coal that allows water and gas to travel through the coal to the well. For gas to be released from the coal, the pressure must be reduced by removing water from the coalbed, a process called dewatering. Dewatering brings large quantities of water (usually saltwater in Kansas) to the surface, which is reinjected deep underground.

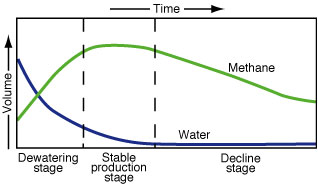

Initial development of coalbed methane wells can take several months because of the large quantities of water that need to be pumped from the coal bed. In general, coalbed methane wells go through three stages during their production history (fig. 2). During the dewatering stage, water production initially exceeds that of methane, but as production continues, the volume of water decreases as the volume of methane increases. A stable production stage is reached when methane production reaches its maximum and water production levels off. During the decline stage, water production remains low and the amount of methane declines until it becomes uneconomical to produce.

Figure 2--Production stages of a coalbed methane well (adapted from Rice and Nuccio, 2000).

An analysis of coalbed methane maximum monthly production rates for individual wells in southeastern Kansas indicates that the median rate (i.e., 50% of wells produce more, 50% of wells produce less) a well makes when it reaches its maximum is 48.9 thousand cubic feet per day (mcf/day). The time necessary for a well to reach its maximum monthly production rate is about 10 months after initial production is reported. From that peak, the annual volume of gas produced from a well starts declining. Within one year after the month of peak production, the monthly production will be down about one-third. As production continues, yearly decline rates will decrease until the declines stabilize at approximately 12% per year in about six years. A coalbed methane well may thus produce gas for several years, even more than a decade.

Flammable gas has occasionally emanated in small amounts from wells in eastern Kansas since drilling in the region began in the latter part of the 19th century. This gas was originally called "shale gas," but some of it, if not most, originated from coal. Low gas prices, small production volumes, no local gathering systems, and the presence of co-produced saltwater made the gas more of nuisance than a resource. In the early part of the 20th century some of this "shale gas" was produced for local consumption.

As a result of the development of the giant gas reserves farther west in the state such as the Hugoton field (discovered 1927), the economic viability of coalbed methane in eastern Kansas was essentially forgotten for most of the 20th century. However, in the early 1970s, geologists and engineers realized that coalbeds could indeed produce commercial quantities of natural gas. This realization primarily came from coalbed methane development in the San Juan basin in southwestern Colorado. Simultaneous efforts by companies and government agencies involved with coal-mine safety in the eastern United States also proved that significant rates of gas flow sometimes occurred from wells that were experimentally drilled ahead of subsurface mining operations. From these realizations coalbed methane exploration efforts were embarked upon in several coal-bearing basins in the United States after 1980.

Relatively little coalbed methane was produced in Kansas before 2000, but rapid development of coalbed methane production was subsequently spurred by several years of intense drilling and successful experimentation with drilling and completion techniques by exploration companies, all occurring in a favorable economic environment of relatively high gas prices. Wellhead gas prices from 2003 to 2008 averaged $8/mcf, with temporary peaks as high as $12/mcf. Since 2008 prices have dropped to around $2/mcf in 2012.

As far as oil and gas drilling goes, coalbed methane wells in Kansas are relatively inexpensive, but their production rates are commensurately modest, although long-lived. The average coalbed methane well in eastern Kansas in 2011 produced 17.6 mcf/day compared to the average well in the venerable Hugoton gas field in southwestern Kansas that produced 46.2 mcf/day. This relatively low rate of pay-out for coalbed methane wells and large upfront costs for gathering systems and water-disposal wells impose a peculiar set of economic conditions on coalbed methane development that encourages large-scale operations. Quantity, in a sense, becomes its own quality, so vast acreage tracts are typically assembled and numerous wells are drilled almost on a production-line basis. Three companies (PostRock Energy, Dart Cherokee Basin, and Layne Energy) account for the majority of coalbed methane production in Kansas. In 2011, these companies produced 82% of the state's coalbed methane.

Cumulatively, approximately 316 billion cubic feet (Bcf) of coalbed methane have been produced in Kansas since 2001, which is the year southeastern Kansas gas production started rising dramatically. Production in 2008 (49.1 Bcf) represents the peak of Kansas coalbed methane production (fig. 3), and annual volumes have declined modestly since then mostly due to a lack of drilling in response to low gas prices at the wellhead. In 2011, 40.4 Bcf of coalbed methane constituted 12.9% of Kansas annual gas production.

Figure 3--Eastern Kansas gas production (overwhelmingly due to coalbed methane) and the number of producing coalbed methane wells reported annually (in blue), and total annual production divided by the total number of coalbed methane wells (in green).

To date (November 2011), 7,292 wells have been reported drilled for coalbed methane in eastern Kansas. The peak for drilling was in 2006 when 1,596 wells were drilled, and since then there have been successive declines in the number of coalbed methane wells drilled annually. Under present economic circumstances (mid-2012), where gas prices are running low compared to previous years, future development of coalbed methane will be relatively slow. Too few new gas wells are currently being drilled to compensate for natural depletion of existing wells. In 2010, only 64 wells were drilled for coalbed methane in Kansas. Production of coalbed methane will gradually decrease in Kansas until higher prices for natural gas justify the expense of drilling and developing new wells in undrilled regions.

The drop in coalbed methane production in southeastern Kansas does not mean the resource is being depleted. More accurately, some of it simply cannot be offered to the market given present low gas prices. Many drilling locations in eastern Kansas are still available. Even if production economics and technology do not radically change, coalbed methane production will still be a vital part of the regional economy for many years to come.

Most coalbed methane in southeastern Kansas is from Middle and Upper Pennsylvanian high-volatile B and A rank bituminous coals. Although the coalbeds in eastern Kansas tend to be widely distributed, the primary concern is the thinness of the coalbeds. Evaluation of geophysical logs in eastern Kansas indicates that about 96% of the coal occurs in beds 14-42 inches thick and only 4% occurs in beds thicker than 42 inches. Almost all coalbed methane wells are vertical and have multiple completions in several coalbeds so as to maximize the production of the well. Most operators developing coalbed methane wells will try to produce a coalbed if it is as thin as 1 ft (fig. 4).

Figure 4--Outcrop of a thin coalbed in Cherokee County, Kansas. Photo: Robert S. Sawin.

Figure 5--Coalbed methane well in Neosho County, Kansas. The electrically driven pumpjack is for drawing water from the coalbed so that adsorbed gas can be evolved from the coal. This well has a telemetered production system (note aerial) and has produced 384 million cubic feet of gas in 4 1/2 years. Photo: Ken Recoy, PostRock Midcontinent Production LLC

Major coalbeds that have proved to be significant for their gas production include the Weir-Pittsburg, Mulky, Bevier, Summit, and Riverton coals, all of which were mined in outcrop farther east in eastern Kansas and western Missouri. All these coals vary in thickness, but in general, the thickest coal is the Weir-Pittsburg seam, which in some localities reaches 6 ft in thickness.

Associated with some coals are dark, organic-rich shales, usually 2 to 5 ft thick. Most of these shales directly overlie coals (such as the Excello shale over the Mulky coal, and Little Osage Shale Member over the Summit coal) and also probably contribute gas into the coal. These shales also contain small amounts of uranium, which makes them radioactive and easily detected with gamma-ray instruments in well logs. Such shale beds in the Cherokee, Marmaton, and overlying Lansing-Kansas City Groups may all be candidates for future shale-gas production.

Coal beds in southeastern Kansas generally produce between depths of 600 to 1,200 ft, although elsewhere in the United States production from coals appears to be good down to a depth of about 3,000 ft. Cleats start to compress shut at depths deeper than this, and thus gas may have trouble making it to the well bore. Deeper coalbed methane production in Kansas is thus possible where coal is present in the deeper parts of the Cherokee and Forest City basins. Conversely, water (hydrostatic) pressure, which is the confining mechanism for coalbed methane, becomes weaker with shallower burial, thus gas content in coalbeds becomes commensurately less farther east in Kansas toward the outcrop of the coal.

Tests of gas contents of coalbeds indicate a general northward decrease of the quantity and quality of the gas in the coals. This is associated with a slight decrease in coal rank and indicates the economics of coalbed methane exploration efforts will be more difficult as coalbed methane development proceeds northward.

Kansas Corporation Commission

Conservation Division

Finney State Office Building

130 S. Market, Room 2078

Wichita, KS 67202-3802

316-337-6200

www.kcc.state.ks.us

Kansas Geological Survey

1930 Constant Ave.

Lawrence, KS 66047-3724

785-864-3965

www.kgs.ku.edu

Ayers, W. B., 2002, Coalbed gas systems, resources, and production and a review of contrasting cases from the San Juan and Powder River basins: American Association of Petroleum Geologists, Bulletin, v. 86, no. 11, p. 1,853-1,890.

Baars, D. L., Watney, W. L., Steeples. D. W., and Brostuen, E. A., 1989 (revised 1993), Petroleum--A primer for Kansas: Kansas Geological Survey, Educational Series 7, 40 p. [available online]

Brady, L. L., 1997, Kansas coal resources and their potential for coalbed methane; in, Transactions of the 1997 American Association of Petroleum Geologists Midcontinent Meeting, September 14-16, Oklahoma City, OK, G. McMahan, G., ed. and compl.: American Association of Petroleum Geologists, p. 150-163.

Energy Information Agency, U.S. Department of Energy, 2007, Coalbed methane status map (Panel 1): U.S. Department of Energy, EIA, http://www.eia.gov/oil_gas/rpd/cbmusa1.pdf

Energy Information Agency, U.S. Department of Energy, 2007, Coalbed methane past, present, and future (Panel 2): U.S. Department of Energy, EIA, http://www.eia.gov/oil_gas/rpd/cbmusa2.pdf

Energy Information Agency, U.S. Department of Energy web site: U.S. Department of Energy, EIA, http://www.eia.gov/

Newell, K. D., 2010, Fall may be imminent for Kansas Cherokee basin coalbed gas output: Oil and Gas Journal, v. 108 (February 10), p. 33-40.

Newell, K. D., and Yoakum, R. L., 2010, Kansas coalbed methane play; in, New Plays and Ways, D. F. Merriam, compl.: Kansas Geological Society, Kansas Oil and Gas Fields, v. VI, p. 105-128.

Rice, D. D., and Nuccio, V., 2000, Coal-bed methane--potential and concerns: U.S. Geological Survey, Fact Sheet FS-123-00.

Scott, A. R., 2002, Hydrogeological factors affecting gas content distribution in coal beds: International Journal of Coal Geology, v. 50, p. 363-387.

Kansas Geological Survey, Public Outreach

Web version revised May 2012

http://www.kgs.ku.edu/Publications/pic19/pic19_1.html